Discover the top 15 advantages of double girder cranes for Pakistan’s heavy industries. Learn how these robust Industrial cranes in Pakistan boost productivity, ensure safety, and provide long-term ROI. Get expert strategies and avoid common mistakes.

In the bustling heart of Pakistan’s industrial sector—from the textile mills of Faisalabad and the steel foundries of Lahore to the shipping yards of Karachi—the relentless movement of heavy materials is the lifeblood of production. Efficiency, safety, and reliability aren’t just goals; they are imperatives for profitability and growth. At the center of this logistical dance stands a critical piece of equipment: the double girder overhead crane.

While various industrial cranes in Pakistan are available, double girder EOT (Electric Overhead Travel) cranes have become the undisputed champion for heavy-duty applications. But what exactly makes them the preferred choice for engineers and factory managers across the nation?

This expert guide will delve into the 15 key advantages of double girder cranes, providing you with the knowledge to make an informed decision for your business, backed by proven strategies and crucial pitfalls to avoid.

Defining the Powerhouse: Key Terms

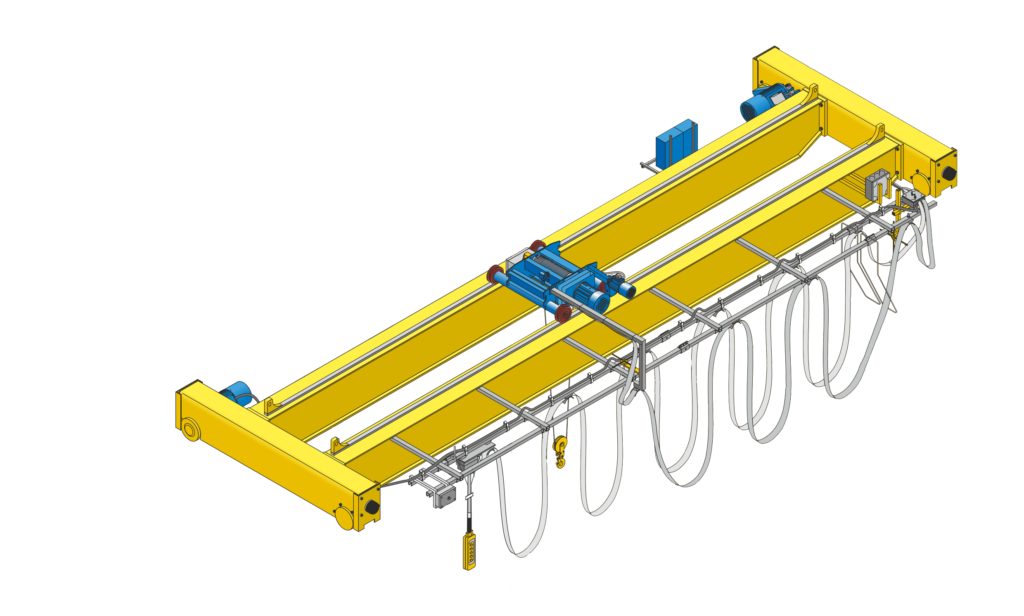

- Double Girder Overhead Crane: A type of heavy crane where the hoist and trolley mechanism operates on top of two parallel girders that form the bridge. This structure is supported at both ends by end trucks that run on elevated runway rails. The dual-girder design inherently provides greater hook height, higher lifting capacities, and exceptional durability compared to its single-girder counterpart.

- Heavy Cranes: A broad category of lifting equipment designed to handle substantial loads, typically exceeding 10 tons. Double girder cranes are a primary example, built for the rigorous demands of moving heavy raw materials, machinery, and finished products.

- Industrial Cranes in Pakistan: This refers to the entire ecosystem of overhead cranes, gantry cranes, jib cranes, and hoists operating within Pakistan’s key sectors. This includes manufacturers, suppliers, service providers, and the equipment itself, tailored to meet local industry standards, power grids, and spatial constraints.

The Top 15 Advantages of Double Girder Cranes

- Exceptional Hook Height: This is arguably the most significant advantage. The hoist is placed on top of the girders, not under them. This design maximizes the vertical lifting space, allowing you to lift loads higher in buildings with limited headroom—a common feature in many Pakistani factories.

- Higher Lifting Capacities: The twin-girder construction distributes the load’s weight more evenly across the entire bridge structure. This makes them ideal for heavy industries in Pakistan like steel, cement, and power generation, where capacities can easily range from 20 tons to well over 500 tons.

- Enhanced Durability and Longevity: Built with robust materials and a redundant design, double girder cranes are designed to withstand years of punishing, high-cycle use. This reduces long-term capital expenditure on replacement equipment.

- Improved Safety and Stability: The dual-beam design offers superior structural integrity, minimizing sway and deflection during lifting and travel. This is critical for the safe handling of expensive, delicate, or hazardous loads, protecting both your assets and your workforce.

- Greater Span Capabilities: Double girder cranes can efficiently bridge wider bays within a facility. This is perfect for large manufacturing halls, warehouses, and assembly shops common in industries like automotive and logistics.

- Flexibility for Auxiliary Hoists: They can easily be equipped with a main and an auxiliary hoist. The main hoist handles the maximum capacity, while a smaller, faster auxiliary hoist is used for lighter, more frequent lifts, drastically improving operational efficiency.

- Optimized Trolley Design: The trolley runs on rails on top of the girders, allowing for a closer approach to the crane runway. This means loads can be positioned with greater precision, right up to walls or other obstacles, maximizing usable floor space.

- Reduced Wheel Load: The load weight is distributed over a longer area and onto more wheels on the end trucks. This translates to lower concentrated forces on the runway rails and supporting building columns, often leading to cost savings on runway construction and reinforcement.

- Lower Overall Headroom: While the hook height is greater, the overall crane height is often comparable or even lower than a single girder crane equipped with a low-headroom hoist. This is a key advantage in facilities with strict height limitations.

- Easier Maintenance Access: Key components like the hoist mechanism, gears, and motors are mounted on top of the bridge, making them more accessible for routine inspection and maintenance compared to components housed inside a single box girder.

- Customization Potential: Double girder cranes can be customized with a vast array of features: cabin operation, radio remote control, automated movement, specialized hooks, and magnet systems, making them adaptable to highly specific industrial processes.

- Long-Term Cost Efficiency (ROI): While the initial investment is higher than a single girder crane, the unparalleled durability, reduced downtime, and lower maintenance requirements result in a significantly better return on investment over its 20-30 year lifespan.

- Increased Productivity: The combination of higher speeds (hoisting, cross travel, long travel), precise load control, and reliability keeps your production line moving faster, directly impacting your bottom line.

- Ideal for Severe Service Applications: They are the default choice for demanding environments such as steel mills (where magnet operations are common), foundries, and forging shops, where heat, dust, and intense usage are daily challenges.

- Future-Proofing Your Investment: The inherent strength of the design allows for potential future upgrades in capacity or operational technology with minimal structural modifications.

5 Proven Strategies for Maximizing Your Double Girder Crane Investment (With Data)

- Integrate Radio Remote Control (RRC): A case study from a Gujranwala-based steel re-rolling mill showed a 25% increase in productivity after switching from pendant control to RRC. The operator had better visibility and control, reducing load swing and positioning time by an average of 40 seconds per lift.

- Implement Predictive Maintenance: Instead of reactive repairs, use scheduled inspections and condition-monitoring tools (vibration analysis, thermal imaging). A textile conglomerate in Karachi reported a 60% reduction in unplanned downtime and a 35% decrease in annual maintenance costs after adopting a predictive maintenance program for their crane fleet.

- Optimize Duty Cycle Specification: Honestly assess your Required Duty Cycle (e.g., CMAA Class D (Heavy Service) vs. Class E (Severe Service)). A Lahore automotive plant initially underspecified a crane for Class C (Moderate Service), leading to premature failure. After respecifying and investing in a Class D crane, they saw a 3x extension in component life.

- Invest in Operator Training: Data from the Pakistan National Safety Council suggests that over 50% of crane-related incidents are due to operator error. Certified training programs that teach load dynamics, safe maneuvering, and daily checks can reduce accident rates by over 70%.

- Choose a Localized Service Partner: Partner with a supplier that has a strong local presence and spare parts inventory. A Faisalabad packaging company reduced mean-time-to-repair (MTTR) from 5 days to under 8 hours by switching to a supplier based in the same industrial estate, ensuring immediate technical support.

Common Mistakes to Avoid When Selecting a Double Girder Crane

- Mistake 1: Prioritizing Lowest Price Over Quality. Cheap, often imported cranes may not comply with local PSI standards and frequently use substandard components, leading to catastrophic failures and costly downtime.

- Mistake 2: Ignoring Building Structure Limitations. Failing to conduct a professional structural analysis of your building’s columns and foundations can lead to unsafe operating conditions and expensive reinforcements later.

- Mistake 3: Underestimating Required Capacity and Duty Cycle. Buying a crane rated for 20 tons for an application that regularly sees 19-ton loads offers no safety buffer and will wear out rapidly. Always build in a capacity buffer.

- Mistake 4: Neglecting Future Needs. Consider if your capacity needs might increase in 5-10 years. A slightly larger investment now can save you from a complete system overhaul later.

- Mistake 5: Overlooking Environmental Factors. Failing to specify the correct class of electrical components (e.g., IP54 for dust and moisture resistance) for Pakistan’s harsh industrial environments will lead to frequent electrical faults.

Answering Your Questions: People Also Ask (PAA)

PAA 1: What is the price of a double girder crane in Pakistan?

The price of a double girder crane in Pakistan is not fixed and depends heavily on several factors:

- Lifting Capacity: A 10-ton crane costs significantly less than a 50-ton crane.

- Span: The distance between the runway rails; a longer span increases the price.

- Duty Cycle: A crane built for severe (24/7) service (Class E) will be more expensive than one for moderate use (Class C).

- Specifications: Features like radio control, cabin operation, and special hooks add cost.

- Brand & Origin: Imported European brands are premium, while quality local Pakistani manufacturers offer competitive pricing.

As a rough estimate, prices for a standard double girder crane can start from PKR 3.5 million for a smaller capacity model and can exceed PKR 20 million for large-capacity, highly customized setups. Always get detailed quotations from reputable suppliers like Loadmate, Pakistan Crane, or reputable international players with local offices.

PAA 2: What is the difference between a single and double girder overhead crane?

The core difference is structural. A single girder crane has one main beam, with the hoist and trolley suspended from it. A double girder crane has two beams, with the hoist and trolley running on top of them.

This fundamental difference leads to practical implications:

| Feature | Single Girder Crane | Double Girder Crane |

|---|---|---|

| Capacity | Lower (Typically up to 20 tons) | Higher (Can exceed 500 tons) |

| Hook Height | Lower (Hoist hangs below girder) | Higher (Hoist sits on top of girders) |

| Cost | Lower Initial Investment | Higher Initial Investment |

| Durability | Good for moderate use | Excellent for heavy/severe use |

| Span | Suitable for shorter spans | Ideal for longer spans |

| Application | Workshops, Warehouses, Light Duty | Steel Mills, Foundries, Heavy Industry |

PAA 3: Which industries in Pakistan use double girder cranes most frequently?

The primary users are heavy industries that involve moving massive, dense materials:

- Steel & Metal Industry: Re-rolling mills, foundries, and forging shops for handling billets, coils, and scrap metal.

- Power Generation: For maintaining turbines, generators, and handling heavy components in hydro, thermal, and nuclear power plants.

- Cement Manufacturing: Moving clinker, raw materials, and heavy machinery.

- Shipping & Ports: In shipyards for constructing and repairing ships, and in ports for handling heavy cargo.

- Automotive Manufacturing: For handling large presses, dies, and vehicle assemblies.

- Heavy Engineering & Fabrication: For assembling large structures and machinery.

Investing in a double girder crane is a strategic decision that empowers Pakistani industries to compete on a global scale through enhanced efficiency, safety, and productivity. By understanding its advantages and implementing the strategies outlined above, you can ensure this powerful asset drives your business forward for decades to come.

Conclusion: Where to Buy the Best Double Girder Crane?

For the best single girder crane price in Pakistan, Orica Engineering offers:

🔹 Custom solutions for any industry

🔹 Affordable pricing (from PKR 1.2M)

🔹 Reliable after-sales service

📞 Contact them today for a free quote!