Introduction

In today’s competitive industrial landscape, manufacturing facilities and warehouses are constantly seeking ways to optimize their material handling processes. The movement of heavy materials represents one of the most critical—and potentially costly—aspects of any industrial operation. Enter the overhead gantry crane, a versatile lifting solution that’s transforming how businesses handle heavy loads with unprecedented efficiency and safety. As we move through 2025, these powerful workhorses are becoming indispensable assets in everything from small workshops to massive industrial complexes. This comprehensive guide will explore everything you need to know about gantry cranes, answering your most pressing questions and helping you understand why this equipment might be the missing piece in your operational optimization strategy.

What is a Gantry Crane?

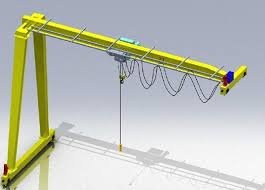

A gantry crane is a type of overhead crane that features a hoist mounted in a fixed machinery house, which then travels along a horizontal beam (the bridge) supported by two or more legs running on fixed rails or wheels. Unlike traditional overhead bridge cranes that rely on building structures for support, gantry cranes are self-supporting through their leg system, making them ideal for both indoor and outdoor applications.

The fundamental components include:

- The Bridge: The main horizontal beam that forms the crane’s primary lifting area

- The Legs/Uprights: Vertical supports that hold the bridge at the required height

- The Hoist and Trolley: The mechanism that lifts and moves loads horizontally across the bridge

- The End Trucks: Wheeled assemblies that allow the entire crane to move along rails or floor surfaces

Gantry cranes come in various configurations to suit different applications. Full gantry cranes feature legs that run on ground-level tracks, making them perfect for outdoor applications like shipping yards and construction sites. Semi-gantry cranes combine one ground-supported leg with one leg that runs on an elevated runway, ideal for facilities where one side of the work area has structural support available. The versatility in design means there’s a gantry crane solution for nearly every material handling challenge.

How Does a Gantry Crane Work?

Understanding the operation of a gantry crane is crucial for appreciating its value in industrial settings. The working principle combines simple mechanics with sophisticated control systems to create a highly efficient material handling solution.

The operational process follows these key steps:

- Positioning: The crane operator positions the entire gantry structure over the load using either manual pushing, electric drives, or motorized systems

- Lifting: Using the hoist mechanism—which can be electric chain hoists, wire rope hoists, or hydraulic systems—the load is lifted vertically to the required height

- Horizontal Movement: The trolley moves the load horizontally along the bridge beam to position it over the target location

- Transportation: If needed, the entire gantry structure can move along its runway to transport loads across longer distances

- Lowering and Placement: The hoist carefully lowers the load into its final position with precision control

Modern gantry cranes incorporate advanced features like variable frequency drives for smooth acceleration and deceleration, anti-sway technology for precise load positioning, and sophisticated control systems that can include radio remote controls, pendant stations, or even fully automated operation. The beauty of this system lies in its flexibility—whether you’re moving a 1-ton machine component or a 100-ton pressure vessel, the basic operational principles remain the same, just scaled to match the requirement.

What Are the Benefits of Gantry Cranes?

The adoption of gantry crane systems brings numerous advantages that directly impact operational efficiency and bottom-line performance. These benefits explain why industries worldwide are increasingly choosing gantry cranes over alternative material handling solutions.

Key advantages include:

- Space Optimization: Unlike traditional overhead cranes that require extensive runway systems mounted to building structures, gantry cranes utilize floor space without compromising overhead clearance. This makes them perfect for facilities with height restrictions or those that cannot support additional structural loads

- Exceptional Versatility: From portable gantry cranes that can be moved between workstations to massive double girder gantry cranes capable of handling ship components, there’s a configuration for virtually every application

- Reduced Facility Costs: By eliminating the need for reinforced building structures and complex runway systems, gantry cranes significantly reduce initial investment costs compared to traditional overhead cranes

- Enhanced Safety: Properly specified gantry cranes reduce manual handling risks, incorporate multiple safety features including overload protection and limit switches, and provide controlled, predictable load movement

- Outdoor Capability: Their self-supporting design makes gantry cranes ideal for outdoor applications where traditional overhead cranes simply aren’t feasible

- Scalability: As your business grows, gantry crane systems can be modified, expanded, or relocated to meet changing requirements

For businesses looking to maximize their material handling efficiency, the combination of these benefits makes gantry cranes an compelling investment. The team at Orica Engineering specializes in helping companies identify which of these benefits will have the greatest impact on their specific operations.

Gantry Crane vs. Overhead Bridge Crane: Which is Right For My Application?

This is one of the most common questions we encounter, and the answer depends entirely on your specific operational requirements, facility constraints, and long-term plans. Both systems have their place in industrial settings, but understanding the differences is crucial for making the right investment decision.

Overhead bridge cranes (often called overhead traveling cranes) feature a hoist that moves along a horizontal beam, which itself moves along two parallel runways attached to the building structure. These systems are excellent for:

- Facilities with strong enough building structures to support the crane and its loads

- Applications requiring coverage of the entire floor area without leg obstructions

- Environments where maximum headroom is crucial beneath the crane

- Operations with consistent, repetitive lifting patterns in fixed areas

Gantry cranes, by contrast, provide distinct advantages in these scenarios:

- Facilities with weak or insufficient roof structures

- Outdoor applications or buildings without existing runway systems

- Operations requiring flexibility in crane location

- Applications where future facility changes might necessitate equipment relocation

- Work environments with multiple workstations serving different functions

The choice often comes down to your facility’s physical characteristics and operational workflow. A detailed site assessment by experienced professionals like the team at Orica Engineering can provide clarity on which solution will deliver better long-term value for your specific situation.

What Are the Different Types of Gantry Cranes Available?

The diversity in gantry crane designs ensures there’s an optimal solution for nearly every industrial application. Understanding these variations helps in selecting the right equipment for your specific needs.

Common gantry crane types include:

1. Full Gantry Cranes

These feature two vertical legs that run on ground-level tracks, creating a stable, robust structure capable of handling extremely heavy loads. Full gantry cranes are the workhorses of shipyards, heavy fabrication shops, and large-scale construction projects. Their robust construction allows them to handle the most demanding applications while providing reliable, long-term service.

2. Semi-Gantry Cranes

Combining one ground-supported leg with one end truck that runs on an elevated runway, semi-gantry cranes offer a practical solution for facilities where one side of the work area has appropriate structural support. This hybrid approach provides many of the benefits of full gantry cranes while potentially reducing costs and maximizing existing infrastructure.

3. Portable Gantry Cranes

Designed for light to medium-duty applications, portable gantry cranes feature wheeled bases that allow easy positioning around a workspace. These are ideal for maintenance operations, loading docks, and manufacturing facilities where lifting needs change frequently. Most feature adjustable heights and spans to accommodate various load sizes and workspace configurations.

4. Adjustable Gantry Cranes

Featuring telescoping legs or adjustable-width configurations, these cranes provide exceptional flexibility for handling loads of varying sizes. The ability to modify the crane’s dimensions makes them perfect for job shops and facilities with diverse lifting requirements.

5. Single Girder vs. Double Girder Gantry Cranes

- Single girder gantry cranes feature one main beam, making them more economical and suitable for lighter loads and shorter spans

- Double girder gantry cranes incorporate two main beams, providing greater hook height, heavier lifting capacity, and better performance for demanding applications

Each type serves specific operational needs, and the experts at Orica Engineering can guide you through the selection process to ensure you choose the most appropriate configuration for your requirements and budget.

What Specifications Should I Consider When Selecting a Gantry Crane?

Choosing the right gantry crane involves careful consideration of several technical specifications that directly impact performance, safety, and cost-effectiveness. Overlooking any of these factors can lead to inadequate performance or unnecessary expenses.

Critical specifications include:

Lifting Capacity

This is the maximum weight the crane can safely handle. It’s crucial to consider not just current needs but potential future requirements. Industry standards recommend selecting a crane with 15-25% more capacity than your heaviest anticipated load to account for unexpected variations and ensure long-term usability.

Span Width

The distance between the crane’s legs determines the working area width. Consider both current and potential future workspace requirements when determining the optimal span. For larger spans, double girder designs typically provide better stability and performance.

Lift Height

This specification determines how high the hoist can raise loads. Consider clearance requirements for the loads themselves, any attachments being used, and potential future applications that might require additional height.

Duty Cycle

The duty cycle classification (as defined by FEM or HMI standards) indicates how intensively the crane can operate. Applications involving frequent use or heavy loads require cranes with higher duty cycle ratings to ensure reliability and longevity.

Power Systems

Consider whether electric, hydraulic, or manual operation best suits your needs. Electric systems offer the most control and convenience but require power infrastructure. Hydraulic systems provide excellent power density, while manual systems offer simplicity and cost savings for light, infrequent use.

Control Systems

Modern options range from simple pendant controls to sophisticated radio remote systems and even fully automated operation. The choice depends on operator preference, facility layout, and operational complexity.

Environmental Factors

For outdoor applications, consider weather protection, wind resistance, and corrosion protection. Indoor applications might prioritize compact designs and noise reduction.

Consulting with gantry crane specialists like Orica Engineering during this specification phase ensures you select equipment that perfectly matches your operational requirements while providing room for future growth.

What Safety Features Are Essential in a Modern Gantry Crane?

Safety is paramount in any material handling operation, and modern gantry cranes incorporate multiple safety systems to protect both personnel and equipment. Understanding these features helps ensure you select a crane that meets the highest safety standards.

Critical safety systems include:

Overload Protection

This non-negotiable safety feature prevents the crane from lifting loads beyond its rated capacity. Modern systems use sophisticated load sensing technology that can automatically disable lifting functions when overload conditions are detected, preventing structural damage and potential accidents.

Limit Switches

Both upper and lower limit switches automatically stop hoist movement at predetermined points, preventing overtravel that could damage equipment or cause load drops. Advanced systems incorporate multiple limit switches for redundant protection.

Emergency Stop Systems

Instantly removable power from all crane functions, emergency stop buttons must be strategically located for quick access in any operating scenario. Modern systems feature fail-safe designs that ensure stops function even during power failures.

Structural Safety Features

- Bumpers and Buffers: Protect both the crane and facility structures from collision damage

- Wind Brakes: Essential for outdoor applications, these prevent unintended movement during windy conditions

- Anti-Collision Systems: For facilities with multiple cranes, these systems prevent interference between equipment

Electrical Safety

- Ground Fault Protection: Prevents electrical hazards

- Phase Monitoring: Protects motors from damage due to power issues

- Low Voltage Controls: Ensure operator safety at the control station

Regular inspection and maintenance are equally crucial for ongoing safety. Establishing a comprehensive inspection protocol—including daily visual checks, monthly operational tests, and annual comprehensive inspections—ensures your equipment remains in safe working condition. Orica Engineering’s maintenance services can help establish and maintain these critical safety protocols.

How Much Do Gantry Cranes Cost, and What’s the ROI?

Understanding the investment required for a gantry crane system—and the potential return on that investment—helps justify the purchase decision and secure necessary approvals.

Cost factors include:

Initial Equipment Costs

- Portable gantry cranes: $1,000 – $10,000

- Standard single girder gantry cranes: $10,000 – $50,000

- Double girder gantry cranes: $50,000 – $200,000+

- Custom engineered systems: $200,000+

Installation and Infrastructure

Site preparation, electrical work, and installation typically add 15-30% to the equipment cost. This varies based on facility conditions and system complexity.

Operational Costs

Consider power consumption, preventive maintenance, parts replacement, and potential downtime. A well-maintained gantry crane typically costs 2-5% of its initial price annually to maintain.

Return on Investment Considerations

The ROI from a gantry crane investment typically comes from:

- Labor Productivity: Reducing manual handling time by 50-80%

- Damage Reduction: Minimizing product damage from improper handling

- Space Utilization: Optimizing floor space usage

- Safety Improvements: Reducing workplace injuries and associated costs

- Throughput Increase: Enabling faster processing of materials

Most operations achieve full ROI within 12-24 months through these combined benefits. The financial team at Orica Engineering can help you develop a detailed ROI analysis specific to your operation.

Conclusion

As manufacturing and logistics operations continue to evolve in 2025, overhead gantry cranes have proven themselves as indispensable tools for enhancing efficiency, safety, and profitability. Their unique combination of versatility, cost-effectiveness, and performance makes them ideal for a wide range of applications, from small workshops to massive industrial complexes.

The key to successful implementation lies in careful planning, proper specification, and professional installation. By understanding the different types available, the critical specifications to consider, and the safety features required, you can make an informed decision that will deliver value for years to come.

Whether you’re looking to improve your current material handling processes or planning a new facility, gantry cranes offer a proven solution for optimizing your operations. For personalized guidance in selecting the right gantry crane for your specific needs, contact the material handling experts at Orica Engineering for a comprehensive consultation and site assessment.