Introduction:

For factories and workshops in bustling industrial hubs like Karachi and Lahore, efficient material handling is crucial for productivity and safety. If you’re frequently lifting and moving heavy loads, a gantry crane is an invaluable asset. But with various types and specifications, choosing the right one can feel daunting. This guide will cut through the complexity, providing clear answers to your most common questions to help you make an informed decision for your operations in Pakistan.

What is a Gantry Crane?

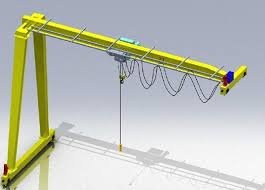

A gantry crane is a type of overhead crane that utilizes a hoist to lift and lower heavy objects. Unlike bridge cranes, which are supported by runways fixed to building structures, gantry cranes are self-supported.

Detailed Explanation: Gantry cranes feature a hoist mounted on a trolley, which runs horizontally along a rail or rails fitted to a single girder or two girders. These girders are supported by upright legs that typically run on wheels or a rail system on the ground. This design makes them highly versatile, as they don’t require connection to a building’s overhead structure, offering flexibility in placement and movement, often outdoors or in large open areas.

How Does a Gantry Crane Work?

A gantry crane operates through a combination of horizontal, vertical, and sometimes longitudinal movements to lift and transport loads.

Detailed Explanation:

- Lifting (Vertical): The hoist, which contains the lifting mechanism (usually an electric motor and wire rope or chain), moves vertically to lift the load.

- Traversing (Horizontal along the beam): The hoist and trolley move horizontally along the bridge beam (girder) of the crane.

- Traveling (Longitudinal): The entire gantry structure, including the legs and bridge, moves along ground-level rails or wheels, covering the designated work area.

These movements are typically controlled via a pendant control, radio remote control, or an operator cabin.

What Are the Benefits of a Gantry Crane?

Gantry cranes offer numerous advantages, particularly for factories and yards that handle heavy materials regularly.

Detailed Explanation:

- Flexibility: They are highly versatile and can be used both indoors and outdoors, making them ideal for shipbuilding, construction yards, and large manufacturing facilities in Karachi and Lahore.

- Cost-Effectiveness: Compared to bridge cranes, gantry cranes often have lower installation costs as they don’t require structural modifications to an existing building.

- Mobility: Many smaller gantry cranes are mobile, allowing them to be moved to different work areas as needed. Larger versions run on rails, providing extensive coverage.

- Load Capacity: They can be engineered to handle extremely heavy loads, ranging from a few tons to hundreds of tons.

- Optimized Space: By lifting materials overhead, they free up floor space for other operations, improving workflow and safety.

What Are the Main Types of Gantry Cranes?

The primary types of gantry cranes include full gantry, semi-gantry, portable gantry, and workstation gantry cranes.

Detailed Explanation:

- Full Gantry Cranes: The most common type, where the bridge beam is supported by two legs that run on ground-level rails. Ideal for large outdoor yards or heavy fabrication shops.

- Semi-Gantry Cranes: One side of the bridge is supported by a leg running on a ground rail, while the other side runs on an elevated runway beam attached to a building structure. This saves floor space on one side.

- Portable Gantry Cranes: Smaller, often on wheels, designed for lighter loads and flexible movement within a workshop. They are easily disassembled and transported.

- Workstation Gantry Cranes: Smaller, sometimes adjustable height, used for specific tasks within a defined area, often hand-pushed or motorized for light to medium loads.

How Do I Determine the Right Lifting Capacity for My Factory?

Choosing the correct lifting capacity for your gantry crane is critical for both safety and efficiency.

Detailed Explanation:

- Maximum Load Weight: Identify the heaviest item your crane will ever need to lift. Always factor in a safety margin.

- Frequency of Lifts: Consider how often heavy loads are lifted. Higher frequency might require more robust components.

- Future Needs: Plan for potential growth or changes in production. Investing slightly more upfront can save significant costs later if your lifting requirements increase.

- Load Dimensions: The size and shape of your typical loads will also influence the required span and height of the crane.

What Safety Features Should I Look for in a Gantry Crane?

Safety is paramount when operating any heavy machinery, and gantry cranes are no exception.

Detailed Explanation: Key safety features include:

- Overload Protection: Prevents lifting loads beyond the crane’s rated capacity.

- Emergency Stop Button: Immediately cuts power in an emergency.

- Limit Switches: Prevent the hoist from exceeding its upper and lower travel limits.

- Anti-Collision Systems: For cranes operating in close proximity, these prevent collisions.

- Audible and Visual Alarms: Warn personnel of crane movement.

- Braking Systems: Reliable brakes for hoist and travel motions.

- Grounding and Electrical Safety: Proper insulation and grounding to prevent electrical hazards.

What Maintenance is Required for a Gantry Crane?

Regular maintenance is essential to ensure the longevity, safety, and optimal performance of your gantry crane.

Detailed Explanation:

- Daily Checks: Visual inspection of ropes, hooks, limit switches, and controls before operation.

- Monthly/Quarterly Inspections: Detailed checks of brakes, electrical components, structural integrity, and lubrication of moving parts.

- Annual Thorough Examinations: A comprehensive inspection by a qualified professional to ensure compliance with safety standards and identify any wear and tear.

- Documentation: Keeping accurate records of all maintenance, repairs, and inspections.

- Operator Training: Ensuring all operators are properly trained and certified.

Conclusion:

Selecting the appropriate gantry crane for your factory in Karachi or Lahore is a significant investment that pays dividends in productivity, safety, and operational efficiency. By carefully considering the type, capacity, safety features, and maintenance requirements, you can choose a crane that perfectly matches your specific industrial needs. Remember, a well-chosen and properly maintained gantry crane is a cornerstone of effective material handling.

You can find the best gantry cranes at www.oricaengineering.com.